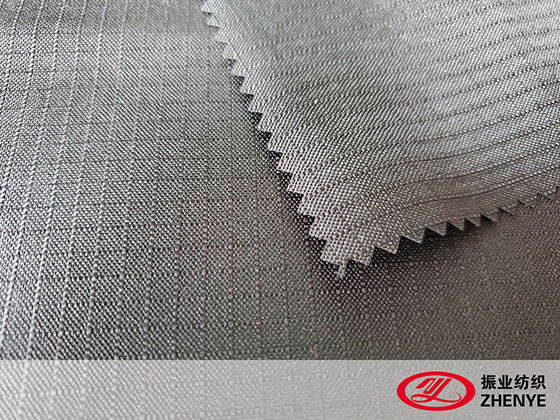

Textile introduces you to the types of Oxford cloth, mainly introduces the following five types of Oxford cloth uses and their advantages and disadvantages, sleeved Oxford cloth, nylon Oxford cloth, full-length Oxford cloth, Teague Oxford cloth, weft Oxford cloth.

1. Nesting Oxford cloth: The warp and weft of this fabric adopts polyester FDY150D / 36F. The fabric is interwoven with a plain weave on a water jet loom with a warp and weft density of 360X210. The gray fabric has a light texture, soft feel, good waterproofness and durability after being treated with slack, alkali, dyeing, antistatic, coating, etc. Good and other advantages.

2. Nylon oxford fabric: the fabric uses 200D nylon variable yarn for warp, and 160D nylon variable yarn for weft. It is a plain weave structure, the product is woven by water spray. After dyeing and finishing, coating process, the grey fabric has the advantages of soft hand feeling, strong drape, novel style, waterproof performance, etc. The cloth mask nylon silk gloss effect.

3. Full-stretch Oxford cloth: The warp and weft fabrics of this fabric are made of polyester DTY300D yarn, which is interwoven on the sprinkler faucet loom with the change of the coarse point of the transparent tissue. After the fabric is relaxed, refined, pre-set, alkali-reduced, and soft-set, the reverse side of the fabric is then rubber-plastic polyester layer. The texture is fine, the gloss is soft, and the waterproof is good.

4. Teague Oxford cloth: The warp yarn of this fabric adopts polyester DTY400D network yarn, and the weft yarn adopts polyester DTY yarn 400D. It adopts TIG texture and is interwoven on water jet (with faucet) loom. The fabric design is novel, the process is unique, the front is protruding, the three-dimensional sense is strong, and it becomes the most prominent part of the fabric. At the same time, the coating (PU) process is also used on the reverse side to make it more waterproof and drape.

5. Weft oxford cloth: The warp of the fabric is made of polyester FDY68D / 24F, the weft is made of FDY150D / 36F, and the weaving process is interwoven by weft weaving in water jet weaving (with multi-arm faucet). The cloth noodles are clear and integrate modernity, artistry and drape. After dyeing, embossing or calendering, the grey fabric has the advantages of strong drape and good water resistance.

EN

EN

English

English Español

Español 中文

中文

.jpg)

.jpg)

.jpg)

-1.jpg)

-1.jpg)