Because of its mid-range denier value, 600D fabric is neither too heavy nor too light, which contributes to its broad usability. The fabric's weave and fiber composition also play important roles in defining its overall performance characteristics.

Material Composition and Weave

600D fabric is commonly made from polyester or nylon fibers, each offering specific benefits. Polyester 600D fabric tends to be more resistant to UV damage and is less prone to stretching, making it a preferred choice for outdoor applications. Nylon 600D fabric, meanwhile, is known for its abrasion resistance and flexibility.

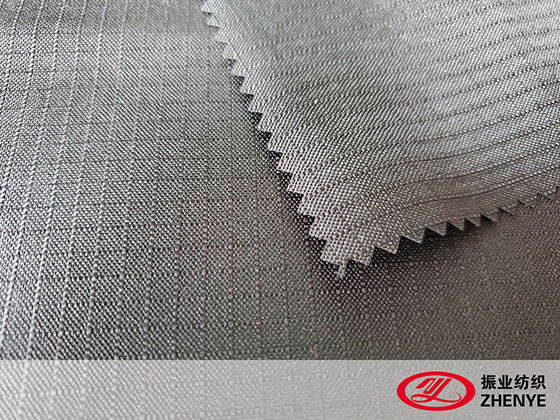

The weave of 600D fabric is typically a plain or basket weave, which enhances durability and contributes to a slightly textured surface. This weave structure helps the fabric withstand wear and tear from daily use and exposure to the elements.

Strength and Durability

One of the key characteristics of 600D fabric is its strength. Thanks to the thickness of its fibers and the tight weave, 600D fabric offers a high level of tensile strength. This makes it resistant to ripping and tearing under moderate stress, which is essential for products subjected to frequent handling or rough conditions.

The durability of 600D fabric also extends to its resistance to abrasion. This means the fabric can endure friction from constant movement or rubbing without quickly wearing out. These properties make 600D fabric a reliable material for backpacks, sports bags, and protective gear.

Water Resistance and Coating

Although 600D fabric is not inherently waterproof, it often comes with special coatings to enhance its water resistance. Common coatings include polyurethane (PU) or polyvinyl chloride (PVC), which create a barrier against moisture.

These coatings not only protect the fabric but also increase its lifespan by preventing water damage and mold growth. As a result, 600D fabric products can be used in outdoor and wet environments with greater confidence.

Texture and Appearance

The texture of 600D fabric is slightly coarse due to the thickness of the fibers and the weave pattern. This texture gives the fabric a rugged and utilitarian look, which is popular in outdoor gear and casual bags.

Despite its durability, 600D fabric maintains a reasonable level of flexibility, allowing it to be shaped and sewn into various designs. It is available in numerous colors and patterns, adding to its appeal for both functional and aesthetic purposes.

Breathability and Comfort

While 600D fabric is sturdy and water-resistant when coated, it is not highly breathable. This characteristic is acceptable or even desirable in many applications where protection against external elements is prioritized over ventilation.

For products like backpacks and luggage, the durability and water resistance of 600D fabric often take precedence over breathability. However, for apparel or items in direct contact with skin, other fabrics with higher breathability may be preferred.

Common Applications of 600D Fabric

The characteristics of 600D fabric make it suitable for a variety of uses. One of the common applications is in bags and backpacks, where strength, abrasion resistance, and water resistance are important.

Outdoor equipment such as tents, camping chairs, and protective covers also frequently utilize 600D fabric due to its durability and weather-resistant coatings. In addition, 600D fabric is found in upholstery and luggage, offering a tough yet affordable solution for everyday wear and tear.

Maintenance and Care

Caring for 600D fabric products is generally straightforward. The fabric's strength and coated surface make it resistant to stains and easy to clean with a damp cloth or mild soap.

It is advisable to avoid prolonged exposure to harsh chemicals or direct sunlight, as these factors may degrade the coating or cause fading over time. Proper storage in dry, shaded places can help extend the lifespan of 600D fabric products.

EN

EN

English

English Español

Español 中文

中文

.jpg)

-1.jpg)

-1.jpg)

-1.jpg)