Specifically, it indicates that every 9,000 meters of this yarn weighs 300 grams. This value places 300D fabric in a medium-weight category, making it strong enough for protection and light enough for comfort and usability. In our manufacturing process, selecting the right denier is crucial to ensure that the finished product offers the desired performance while staying cost-effective and efficient to produce.

One of the appealing features of 300D fabric is its durability. It can withstand abrasion and stress while maintaining flexibility. In applications like backpacks, promotional bags, tool organizers, and soft-shell luggage, customers require a material that does not wear out easily, especially around stress points such as seams and zippers. We have developed several variations of 300D fabric, including those with PU or PVC coatings, to enhance water resistance and structural integrity.

From a production standpoint, 300D fabric is relatively easy to handle. It works well with different types of coatings and lamination, making it adaptable to changing client needs. Whether the end product requires waterproofing, UV protection, or flame retardancy, 300D fabric can be modified accordingly. As a result, our facility often stocks several versions of this material to cater to orders in sectors ranging from travel goods to outdoor furniture covers.

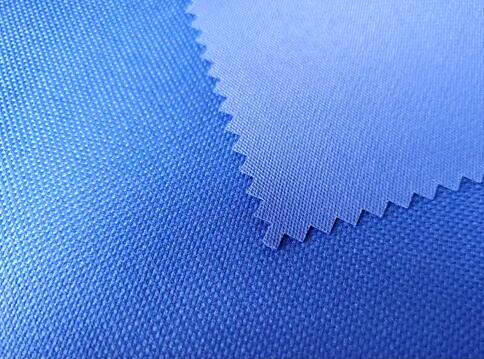

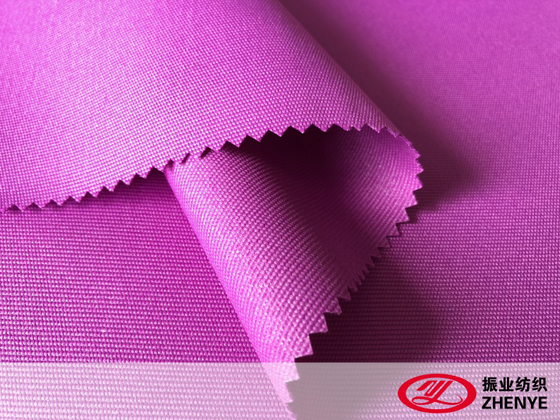

Another advantage we observe is the flexibility in finishing techniques. 300D fabric accepts printing and dyeing well, allowing for branding, patterns, and color customization without compromising fabric strength. For many of our clients in retail packaging and custom bag production, the aesthetic aspect is just as important as performance. Our ability to provide digitally printed or screen-printed 300D fabric gives them a visual edge in competitive markets.

The lightweight nature of 300D fabric also makes it ideal for products that must be carried or worn for extended periods. Compared to heavier materials such as 600D or 1000D, 300D fabric offers a good trade-off between weight and toughness. In our product lines for travel gear and promotional items, this balance allows us to meet design and budget constraints without sacrificing quality.

In terms of environmental adaptability, 300D fabric holds up well under various conditions. We supply it for use in tents, car covers, and rainwear, where resistance to moisture and sunlight is essential. When treated with the appropriate coatings, the fabric offers a reliable shield against elements. Our R&D team has also worked on enhancing the recyclability of 300D fabric, using more eco-friendly coatings and base yarns derived from post-consumer plastics.

Cost-efficiency is another factor driving the popularity of 300D fabric. Compared to heavier denier options, it provides a more affordable alternative without drastically reducing functionality. As manufacturers, we can optimize our production processes and offer clients scalable solutions by using this fabric across different product types. This efficiency also contributes to faster times and greater flexibility in order fulfillment.

One often overlooked advantage is how 300D fabric contributes to machine efficiency during assembly. Its moderate thickness allows for smoother cutting, stitching, and heat-sealing processes. This reduces wear on factory equipment and increases output per hour, helping us maintain consistent production quality and volume, even on large orders.

Customization in terms of texture is another reason for the popularity of 300D fabric. Our facility can produce variants with ripstop weaves, matte or glossy finishes, and embossed patterns. Each version of 300D fabric has specific use cases — for example, a ripstop weave is preferred in tents and outdoor applications, while a matte finish might be chosen for luxury promotional totes.

We also see regular demand for 300D fabric in educational and health sectors. Items like school bags, medical storage kits, and utility pouches rely on the fabric’s durability and ease of cleaning. With appropriate coatings, these products maintain hygiene standards while ensuring long-term use.

EN

EN

English

English Español

Español 中文

中文-1.jpg)

-1.jpg)

-1.jpg)

-1.jpg)

-2.jpg)