Before exploring its applications and processing, it is useful to understand what makes 600D fabric unique.

Key Features:

Durability: The fabric has a high denier count of 600, making it strong and resistant to tearing.

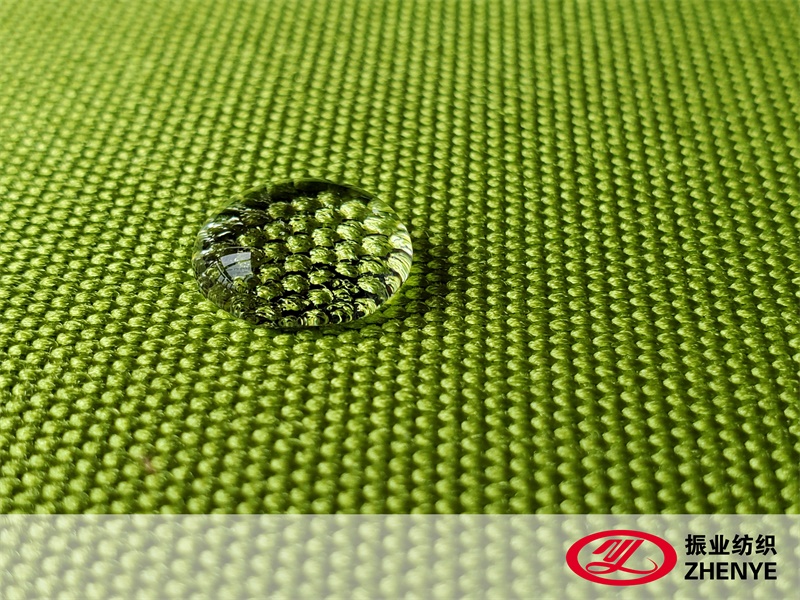

Water Resistance: Many 600D fabrics are coated with PVC or PU, providing protection against moisture.

Flexibility: Despite its strength, it remains flexible enough for various shapes and designs.

Abrasion Resistance: Ideal for products that undergo frequent friction and rough handling.

Ease of Maintenance: Can be cleaned easily, making it suitable for everyday use.

These characteristics allow 600D fabric to serve a wide range of applications.

Applications of 600D Fabric

1. Bags and Backpacks

600D fabric is commonly used in the production of backpacks, school bags, and travel bags.

Benefits:

Withstands daily wear and heavy loads.

Offers protection to contents due to its thickness.

Can be dyed in various colors and printed with patterns for aesthetic appeal.

From casual backpacks to professional laptop bags, the fabric combines durability and style.

2. Luggage and Travel Gear

Luggage, duffel bags, and travel organizers often use 600D fabric for its strength and ability to endure rough handling during travel.

Benefits:

Resistant to tearing during transit.

Provides a lightweight yet sturdy structure.

Compatible with coatings to enhance water resistance.

3. Outdoor Equipment

Tents, camping chairs, tarps, and outdoor gear frequently utilize 600D fabric due to its resilience and weather resistance.

Benefits:

Handles exposure to wind, sun, and moisture.

Retains shape and strength in demanding environments.

Easy to clean after outdoor use.

4. Protective Covers

The fabric is also used to make protective covers for motorcycles, vehicles, machinery, and equipment.

Benefits:

Shields items from dust, dirt, and light rain.

Durable enough to withstand repeated handling and movement.

Lightweight, allowing easy installation and removal.

5. Industrial and Utility Products

600D fabric finds applications in tool bags, utility pouches, and workwear, offering a combination of durability and convenience.

Benefits:

Supports heavy-duty use in industrial environments.

Resistant to abrasion from tools and equipment.

Maintains shape and integrity under repeated stress.

Processing of 600D Fabric

The production and processing of 600D fabric involve several stages to ensure quality and functionality.

1. Weaving

600D fabric is made using a high-density polyester or nylon yarn. The yarn is woven in a plain or basket pattern, creating a durable structure.

Key Points:

Ensures uniform strength across the fabric.

Allows for flexibility while maintaining high denier count.

Forms the foundation for coatings and treatments.

2. Dyeing and Printing

After weaving, the fabric is dyed or printed to achieve the desired color and pattern.

Key Points:

Dyeing provides colorfastness and uniformity.

Printing adds decorative designs, logos, or patterns.

Advanced techniques allow multi-color and gradient designs.

3. Coating

To enhance water resistance, 600D fabric is often coated with PU (polyurethane) or PVC (polyvinyl chloride).

Key Points:

Improves durability against moisture and stains.

Provides additional structural strength.

Can be applied to one or both sides depending on the application.

4. Cutting and Sewing

Fabric is cut into specific patterns and sewn into final products such as bags, tents, or covers.

Key Points:

Precision cutting ensures minimal waste.

Reinforced stitching enhances strength in high-stress areas.

Specialized sewing techniques can improve durability and aesthetics.

5. Quality Control

Finished fabric and products undergo quality inspections to ensure consistency, strength, and resistance to wear.

Key Points:

Tests may include abrasion resistance, tear strength, and water repellency.

Ensures that products meet industry standards and user expectations.

EN

EN

English

English Español

Español 中文

中文.jpg)

.jpg)

.jpg)

-2.jpg)

-1.jpg)

-1.jpg)