600D fabric is typically made from polyester or nylon, both of which are generally safe for everyday use when properly manufactured.

Key safety considerations include:

Chemical additives: Some 600D fabrics may include flame retardants, water repellents, or dye chemicals. Consumers should verify that the fabric complies with local safety standards, such as REACH in Europe or CPSIA in the United States.

Skin sensitivity: Polyester and nylon are synthetic fibers, and a small portion of people may experience irritation if the fabric is not properly finished or if it contains residual chemicals.

Odor and off-gassing: Newly manufactured synthetic fabrics may emit a mild odor due to production residues, which typically fades after airing.

600D fabric is considered safe when sourced from reputable manufacturers and when it meets relevant safety certifications.

How Environmentally Friendly Is 600D Fabric?

Environmental concerns are increasingly significant as consumers focus on sustainability. 600D fabric is often produced from polyester or nylon, which are derived from petrochemicals. The environmental impact depends on production methods, energy use, and end-of-life disposal.

Important points include:

Energy consumption and emissions: The production of synthetic fibers involves energy-intensive processes and carbon emissions.

Microplastic shedding: Synthetic textiles can release microfibers during washing, which may enter waterways and contribute to microplastic pollution.

Recyclability: Some 600D fabrics can be recycled, especially if made from recycled polyester (rPET). However, recycling depends on local facilities and whether the fabric is blended with other materials.

For consumers seeking more sustainable options, 600D fabric made from recycled polyester or combined with eco-friendly coatings may be preferable.

Is 600D Fabric Suitable for Outdoor Use?

Outdoor performance is a primary public concern because 600D fabric is widely used for backpacks, tents, and protective covers. Its suitability depends on factors such as water resistance, UV stability, and abrasion resistance.

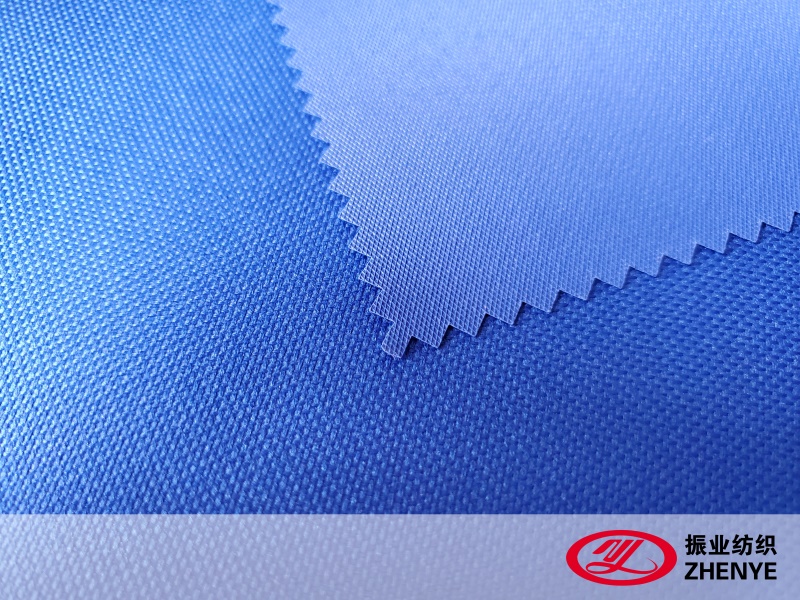

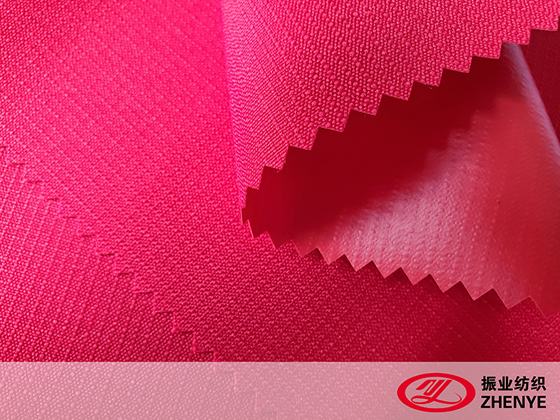

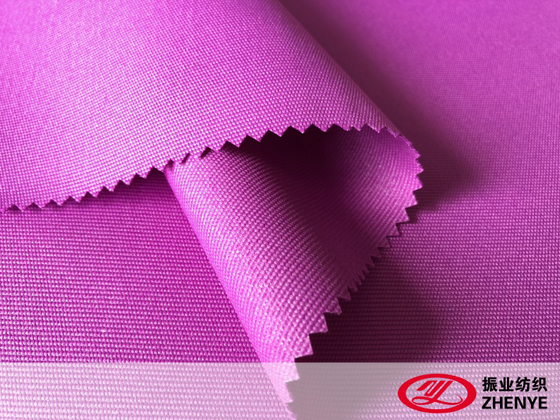

Water resistance: 600D fabric is often coated with PVC, PU, or TPU to improve water resistance. The level of water protection varies by coating type and thickness.

UV resistance: Prolonged exposure to sunlight can cause fading and reduced strength over time. UV-resistant coatings or additives can extend durability.

Abrasion resistance: 600D fabric is known for good abrasion resistance, making it suitable for high-wear applications such as bags and outdoor gear.

When choosing 600D fabric products for outdoor use, consumers should verify the coating type and water resistance rating.

How to Ensure Quality and Avoid Misleading Claims?

Quality consistency is a common concern, as the same “600D” label can represent different performance levels depending on material and manufacturing.

Consumers should pay attention to:

Fiber type: Nylon 600D typically has higher strength than polyester 600D, though both offer good durability.

Weave and finish: The weave density and finishing processes (such as laminating or coating) significantly affect performance.

Coating type: PVC coating is common for heavy-duty use, while PU and TPU coatings can offer better flexibility and lighter weight.

To avoid misleading claims, consumers can check product specifications such as:

Tensile strength

Water resistance (e.g., hydrostatic head)

Abrasion test results

UV resistance ratings

EN

EN

English

English Español

Español 中文

中文

.jpg)

.jpg)

-2.jpg)

-1.jpg)