Material Composition and Manufacturing

PU fabric is the product of a lamination or coating process. The base substrate, or backing, is typically a woven or knitted textile. Common substrates include polyester, nylon, and cotton. The choice of substrate significantly influences the final fabric's weight, drape, and tensile strength. Polyurethane, a polymer formed by reacting a polyol with a diisocyanate, is prepared in a liquid form, often as a solution or as a 100% solid formulation.

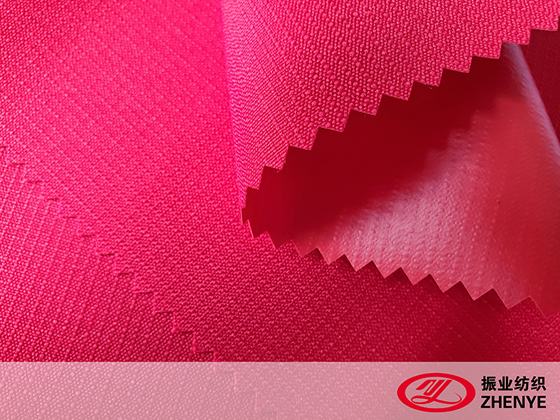

In the coating process, this liquid polyurethane is applied to one side of the base fabric using techniques such as direct coating, where the PU is spread with a knife, or transfer coating, where the PU is first cast onto a release paper and then thermally laminated to the fabric. The coated material then passes through ovens to cure and solidify the polyurethane, forming a continuous film. This film can be made in varying thicknesses, from a thin, flexible layer to a substantial, durable coating. The surface of the PU layer can also be embossed during manufacturing to create textures that mimic leather, provide a matte finish, or achieve other specific tactile qualities.

Physical and Functional Properties

The properties of PU fabric arise from the synergistic combination of the textile backing and the polyurethane coating. The fabric backing provides structural integrity, tear resistance, and a familiar textile hand from its reverse side. The PU coating is responsible for several key functional attributes.

Firstly, it acts as a barrier. The continuous polymer film is inherently water-resistant and, in many formulations, can be made waterproof and windproof. This makes PU-coated fabrics suitable for outerwear and protective gear. Secondly, the coating enhances durability. It provides resistance to abrasion, scuffing, and soiling, as the smooth surface is easier to clean than a raw textile. The PU layer also offers a degree of resistance to oils and many chemicals, depending on its formulation. Furthermore, the material maintains flexibility across a range of temperatures and does not become stiff in cold conditions as some plastic films can. The breathability of PU fabric, however, is generally low, as the solid film blocks the passage of air and moisture vapor, though microporous and hydrophilic PU coatings have been developed to address this limitation for certain high-performance applications.

Common Applications and Uses

The utility of PU fabric is evident in its diverse range of applications, driven by its balance of performance, aesthetics, and cost.

Apparel and Footwear: It is widely used as a leather alternative in jackets, bags, shoes, and accessories. Its uniform quality, ease of cleaning, and lower cost compared to genuine leather are factors in its adoption.

Outdoor and Protective Gear: Due to its water-resistant and windproof qualities, it is employed in rainwear, protective workwear, covers for equipment, and lightweight tents or tarpaulins.

Upholstery and Interior Design: PU fabric is used for furniture upholstery, automotive interiors (seats, door panels, headliners), and wall coverings. It offers durability, ease of maintenance, and a consistent appearance.

Technical and Industrial Uses: It serves in applications requiring a durable, flexible barrier, such as inflatable products, medical mattress covers, and certain types of industrial diaphragms or gaskets.

Considerations and Comparisons

When selecting or working with PU fabric, several practical factors are relevant. A comparison with polyvinyl chloride (PVC) fabric, another common coated material, is often instructive.

|

Aspect |

PU Fabric |

PVC Fabric |

|

Material Feel |

Generally softer, more flexible, and textile-like; less plastic feel. |

Can be stiffer, especially at lower temperatures; more pronounced plastic feel. |

|

Environmental Impact |

Production and disposal concerns exist; some biodegradable formulations are developed. |

Contains chlorine and plasticizers (like phthalates); recycling is challenging. |

|

Durability |

Good abrasion resistance; may be prone to hydrolysis (degradation by moisture and heat) over time. |

Excellent abrasion and tear resistance; less susceptible to hydrolysis. |

|

Cost |

Typically more expensive than standard PVC coatings. |

Often a lower-cost option for coated fabrics. |

Other considerations include care and maintenance: PU fabrics are usually wipe-clean but can be degraded by harsh solvents. Their performance lifespan can be affected by prolonged exposure to ultraviolet light, which may cause the coating to become tacky or crack. From a production standpoint, it is easier to achieve consistent color and texture across large batches with PU fabric compared to natural leather, which is a significant advantage for mass manufacturing.

EN

EN

English

English Español

Español 中文

中文

.jpg)

.jpg)

.jpg)

-2.jpg)

-1.jpg)