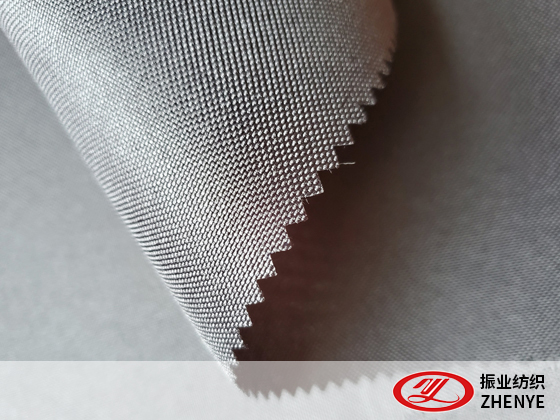

Characteristics and Applications of 600D Fabric

600D fabric is a category of synthetic textile distinguished by its yarn thickness and construction. The "D" stands for denier, a unit of measurement that describes the linear mass density of a continuous filament yarn. Specifically, a 600 denier yarn weighs 600 grams per 9,000 meters of its length. This measurement correlates with the yarn's thickness and, by extension, the fabric's durability and weight. Typically woven from nylon or polyester filaments, 600D fabric is engineered to balance strength, flexibility, and cost, making it a standard material for products requiring resilience to wear and tear. Its properties are not intrinsic to the denier alone but result from the interplay of fiber type, weave pattern, and potential coatings.

Common Applications and Product Uses

The functional profile of 600D fabric—its notable tear and abrasion resistance combined with manageable weight—makes it suitable for a diverse range of durable goods. It is frequently selected for applications where a material tougher than standard packcloth or canvas is needed, but where the weight and rigidity of higher-denier fabrics like 1000D would be impractical. The following table outlines its primary areas of use.

Application SectorSpecific Product ExamplesRationale for Use

|

Application Sector |

Specific Product Examples |

Rationale for Use |

|

Luggage & Bags |

Checked luggage shells, rolling duffels, backpacks (especially for travel or tactical use), laptop sleeves, and tool bags. |

Provides structural durability to withstand handling during transport and resistance to scuffing. |

|

Outdoor Gear |

Tent floors, lightweight tarps, gear storage sacks, and the body of some soft-sided coolers. |

Offers a balance of water resistance (when coated), puncture resistance, and packable weight. |

|

Protective Covers |

Covers for motorcycles, outdoor furniture, machinery, and vehicle seat covers. |

The fabric's resilience protects against UV degradation, minor impacts, and environmental dirt. |

|

Tactical & Workwear |

Components of tactical vests, hydration pack carriers, work aprons, and reinforced sections on heavy-duty backpacks. |

Withstands rigorous physical activity, abrasion from equipment, and frequent use in demanding environments. |

|

Sporting Goods |

Sports duffel bags, equipment carriers for martial arts or fitness, and certain types of protective padding or cases. |

Meets the need for durable, washable, and often water-resistant material for gear that is regularly used and transported. |

Material Properties and Performance

The performance of 600D fabric is defined by several key physical characteristics that stem from its construction.

- Durability and Strength: The primary attribute of 600D fabric is its resistance to mechanical stress. The thickness of the 600-denier yarns contributes to high tensile and tear strength. When woven in a tight, plain or ripstop pattern, the fabric can withstand significant pulling forces and abrasion against rough surfaces. This makes it less likely to rip or develop holes during normal use compared to lower-denier fabrics. However, its abrasion resistance is generally lower than that of 1000D fabrics, placing it in a mid-range category of rugged textiles.

- Weight and Flexibility: Despite its strength, 600D fabric maintains a degree of flexibility and a weight that allows for functional design. Products made from it can be shaped and folded without excessive stiffness. This balance is crucial for items like backpacks and luggage, which require durable shells that are not overly cumbersome. The fabric's drape and handling characteristics are influenced by the type of polymer (nylon or polyester) and the presence of any coatings or laminates.

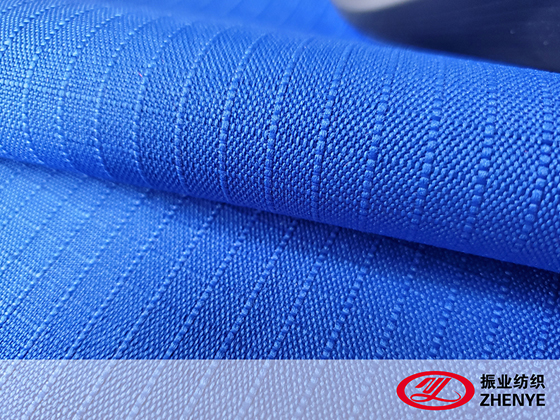

- Water and Element Resistance: In its untreated, woven state, 600D fabric is not waterproof. However, it is almost universally treated with a coating or laminate to enhance its performance. A polyurethane (PU) coating is common, providing water resistance by sealing the weave. For higher performance, a laminated membrane like TPU can be applied. These treatments also improve the fabric's resistance to mildew and UV degradation, though prolonged sun exposure will eventually cause gradual weakening and fading of the fibers.

- Maintenance and Longevity: The synthetic nature of 600D fabric makes it relatively easy to maintain. It is typically washable and dries quickly. Stains are less likely to be absorbed into coated versions. Its longevity is influenced by the quality of the coating adhesion; peeling or delamination of the coating from the fabric substrate is a more common failure mode than the actual breaking of the 600D yarns themselves.

Manufacturing and Selection Considerations

The production and specification of 600D fabric involve technical decisions that affect the end product's quality and suitability.

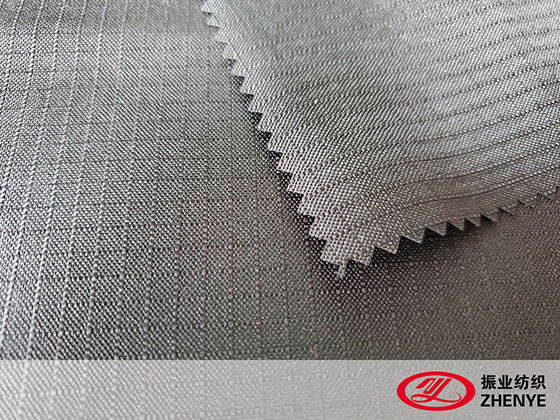

Fiber Type Choice: The selection between nylon and polyester filaments is foundational. Nylon 6,6 often provides greater abrasion resistance and a softer hand feel but may be more susceptible to UV degradation and water absorption. Polyester offers better UV resistance, lower water absorption, and often a lower cost, with slightly less elasticity than nylon. The choice depends on the prioritized performance metrics for the final product.

Weave Pattern and Construction: The weaving pattern impacts the fabric's behavior. A plain weave offers a uniform, strong surface. A ripstop weave incorporates thicker reinforcement threads at intervals, creating a grid that resists the propagation of tears. The thread count (the number of yarns per square inch) also affects density, weight, and potential for coating penetration.

Coating and Finishing Processes: The application of a PU coating or laminate is a critical post-weave step. The coating weight (measured in grams per square meter) determines the level of water resistance and stiffness. Additional finishes may include dyeing for color, calendaring for a smoother surface, or treatment with durable water repellent (DWR) chemicals to cause water to bead on the surface.

Quality Gradients and Specifications: Not all 600D fabric is identical. Quality varies based on the grade of the polymer, the consistency of the yarn, the evenness of the coating, and the environmental controls during manufacturing. Product designers must specify these parameters, understanding that a higher-quality 600D fabric with a robust coating will outperform a lower-grade version with the same denier rating in real-world durability tests.

EN

EN

English

English Español

Español 中文

中文

.jpg)

.jpg)

.jpg)