Material Composition and Weave Differences

600D fabric factory is typically made from polyester or nylon fibers, which are woven into a relatively tight plain or ripstop weave. This weave structure gives the fabric strength and abrasion resistance while maintaining flexibility. Polyester 600D fabric is often coated with polyurethane (PU) or polyvinyl chloride (PVC) to enhance water resistance, while nylon 600D may be treated for extra durability and UV protection.

Compared with lighter fabrics, such as 300D or 420D textiles, 600D fabric uses thicker fibers, providing a stronger and more durable surface. Lighter fabrics are often more flexible, softer, and easier to fold, making them suitable for items like ultralight backpacks or small pouches. In contrast, heavier fabrics such as 900D, 1000D, or 1200D textiles have thicker fibers and denser weaves, offering greater durability but adding weight and stiffness. Canvas and cotton-based fabrics differ further, as they are natural fibers that absorb moisture more readily and generally require additional coatings or treatments for water resistance.

Durability and Abrasion Resistance

One of the key differences between 600D fabric and other textiles lies in durability. The moderate denier and tight weave provide a balance between strength and weight. 600D fabric can resist moderate abrasion, tearing, and stretching, making it suitable for backpacks, luggage, and equipment covers that experience regular but not wear.

Lighter fabrics, such as 210D or 300D polyester, are less resistant to abrasion and may develop holes or fraying more quickly under heavy use. On the other hand, heavy-duty fabrics like 1000D nylon or Cordura offer higher abrasion resistance, suitable for tactical gear, heavy-duty outdoor equipment, or industrial applications. However, the added thickness increases overall weight and may reduce flexibility, making the item bulkier and less portable. Therefore, 600D fabric provides a middle ground, offering sufficient durability for daily use without excessive weight or stiffness.

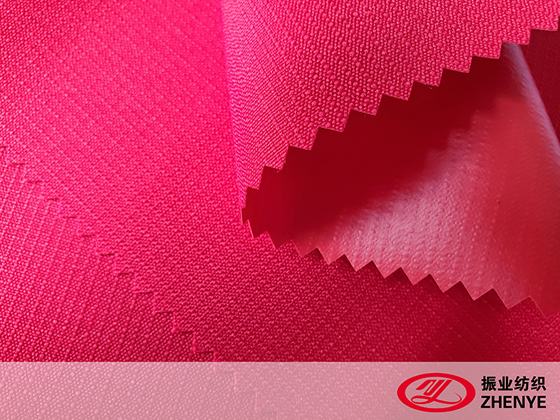

Water Resistance and Surface Coatings

600D fabric can be treated with PU, PVC, or other coatings to improve water resistance. This makes it suitable for backpacks, travel bags, and outdoor gear, as it helps prevent water from seeping into the fabric during rain or accidental spills. The coated surface also provides some resistance to dirt and staining, making cleaning easier.

In comparison, lighter fabrics may have thinner coatings or none at all, which limits water resistance. Heavy-duty fabrics, in contrast, often include thicker coatings or laminated surfaces to achieve near-waterproof performance, which is useful for high-performance outdoor gear or marine applications. Natural fabrics such as cotton or canvas require additional waterproofing treatments, such as wax or spray-on coatings, as they are not inherently water-resistant. Therefore, 600D fabric offers a practical level of water resistance suitable for everyday use while remaining flexible and manageable.

Weight, Flexibility, and Cost Considerations

Another notable difference between 600D fabric and other textiles is weight and flexibility. 600D fabric is heavier than 300D or 420D fabrics but lighter and more flexible than 1000D or higher denier fabrics. This balance allows manufacturers to create products that are strong enough for moderate use while still being portable and easy to handle.

Cost is also a factor. 600D fabric is generally less expensive than very high-denier fabrics such as 1000D or 1200D Cordura, which require more material and specialized production processes. Lighter fabrics are often cheaper but may not meet durability requirements for heavy daily use. Choosing 600D fabric allows a balance of cost, weight, and performance, making it a popular choice for products that need moderate strength without significant expense or bulk.

EN

EN

English

English Español

Español 中文

中文

.jpg)

.jpg)

-1.jpg)

-1.jpg)