PVC fabric is made by coating or laminating a base fabric, such as polyester or cotton, with a layer of PVC, which provides protective and decorative properties. PVC fabrics are applied in products ranging from outdoor awnings, tents, and tarpaulins to inflatable items, rainwear, and upholstery.

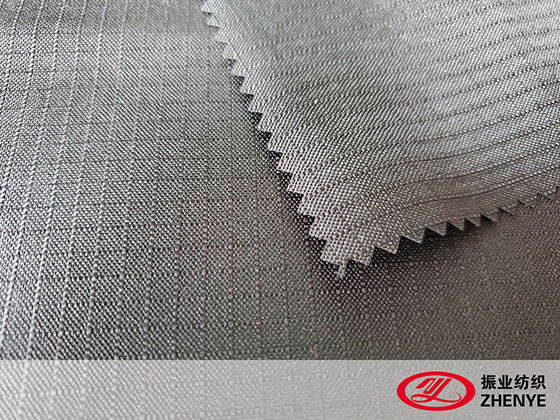

Standard PVC-Coated Fabric

Standard PVC-coated fabric is one of the common types. It typically consists of a polyester base fabric coated with a single layer of PVC on one or both sides. The PVC coating provides water resistance, some level of UV protection, and basic abrasion resistance.

This type of fabric is often used for applications such as tarpaulins, banners, raincoats, and simple outdoor covers. Standard PVC-coated fabric is flexible, lightweight, and relatively easy to clean, making it practical for everyday use. Its straightforward production method and moderate cost contribute to its widespread use in various industries.

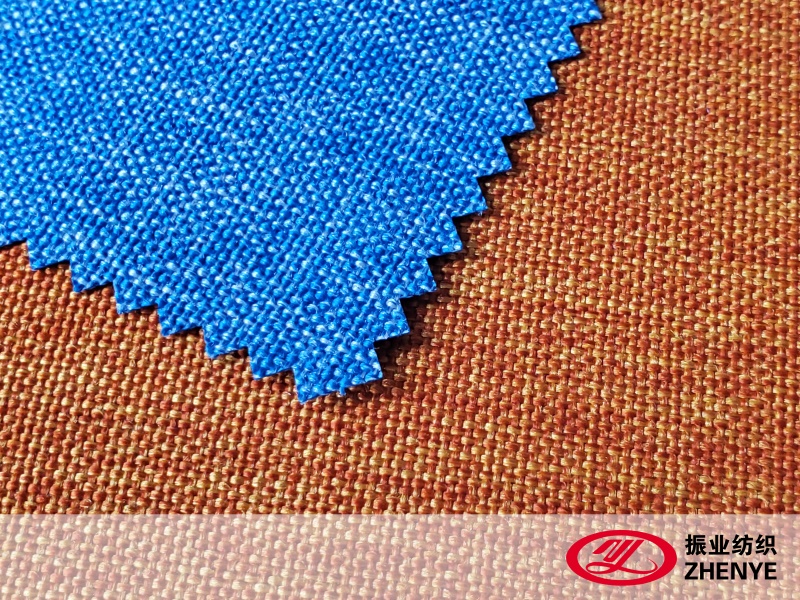

High-Density PVC Fabric

High-density PVC fabric is designed for applications that require stronger durability and resistance to wear. The base fabric in this type is tightly woven, usually from polyester or nylon, and then coated with multiple layers of PVC.

The additional density and coating thickness improve puncture resistance, tensile strength, and durability under heavy use. High-density PVC fabric is commonly used for industrial tarps, truck covers, inflatable structures, and heavy-duty outdoor equipment. Its strength allows it to withstand repeated handling and exposure to wind, rain, and abrasion. This type of fabric is slightly heavier than standard PVC fabric but offers enhanced protection and longevity.

Transparent or Clear PVC Fabric

Transparent PVC fabric, also known as clear PVC, is coated or laminated over a see-through base material, usually polyester. This type of fabric combines the protective qualities of PVC with visibility, making it suitable for applications where light transmission or visual access is important.

Clear PVC fabric is often used in greenhouse panels, protective curtains, boat windows, and outdoor shelters where natural light is needed while maintaining protection from wind and water. Depending on the production method, the fabric can vary in thickness, flexibility, and UV resistance. This type allows users to monitor conditions while still benefiting from the material's water-resistant and durable properties.

Flame-Retardant PVC Fabric

Flame-retardant PVC fabric is treated or formulated to meet specific safety standards, reducing the risk of ignition and slowing the spread of fire. The PVC coating is combined with additives that enhance fire resistance while maintaining flexibility and durability.

This type of PVC fabric is used in environments where fire safety is a concern, such as tents, exhibition booths, protective covers, and industrial curtains. Flame-retardant PVC fabrics are subject to regulatory testing to ensure compliance with fire safety standards, making them suitable for commercial and public applications where safety is required.

PVC fabric comes in various types, each designed for specific uses and environmental conditions. Standard PVC-coated fabric offers basic water resistance and flexibility for general applications, while high-density PVC fabric provides enhanced durability and strength for heavy-duty use. Transparent or clear PVC fabric allows light transmission and visibility while maintaining protection, and flame-retardant PVC fabric improves safety in environments where fire risks are a concern. Understanding these types and their characteristics helps manufacturers, designers, and users select the right PVC fabric for their intended applications, balancing durability, functionality, and safety.

EN

EN

English

English Español

Español 中文

中文

.jpg)

.jpg)

.jpg)

-1.jpg)

-2.jpg)